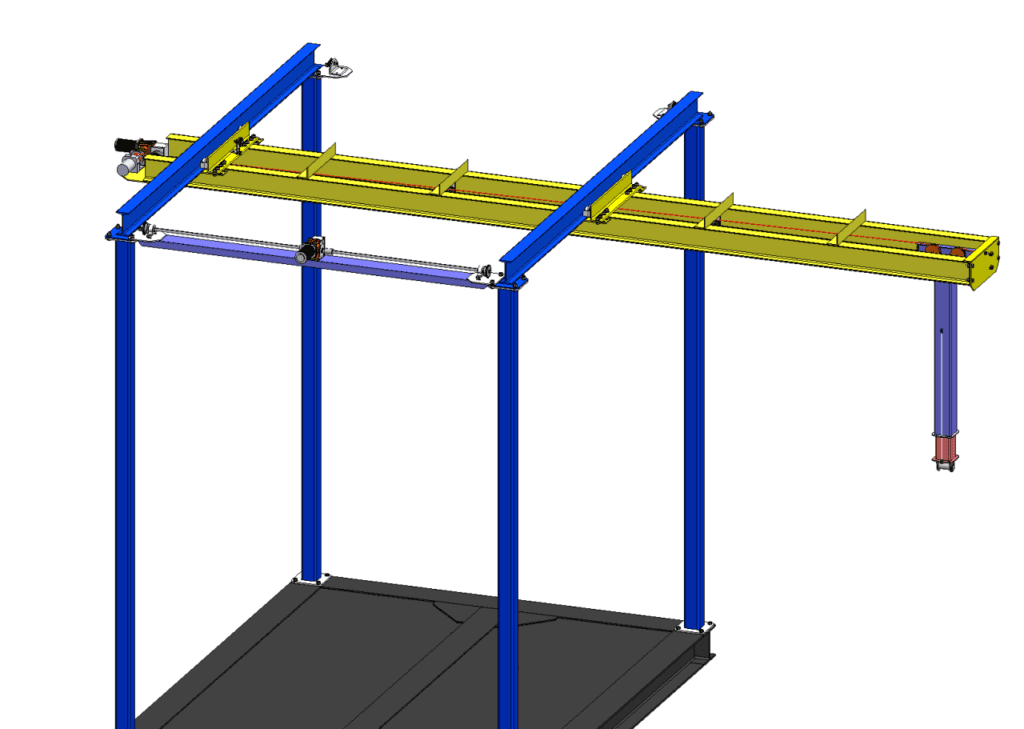

RC1000 is a 3-axis custom crane used to pick up a cathode plate from a kiln, bring it to a piece of recovery equipment, collect the deposited material and return it to the electrolytic pot.

Custom design

Why not a regular crane? Well… the electrolytic process runs quite hot, close to 800°C. So any regular hoist with electrical components would not survive.

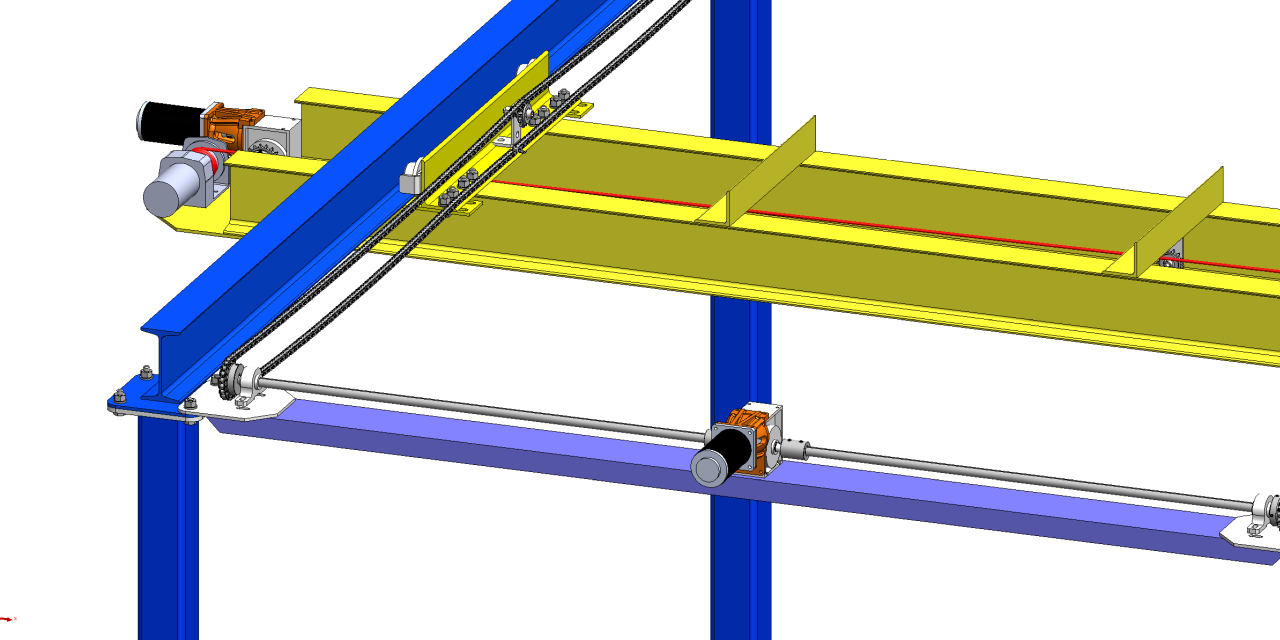

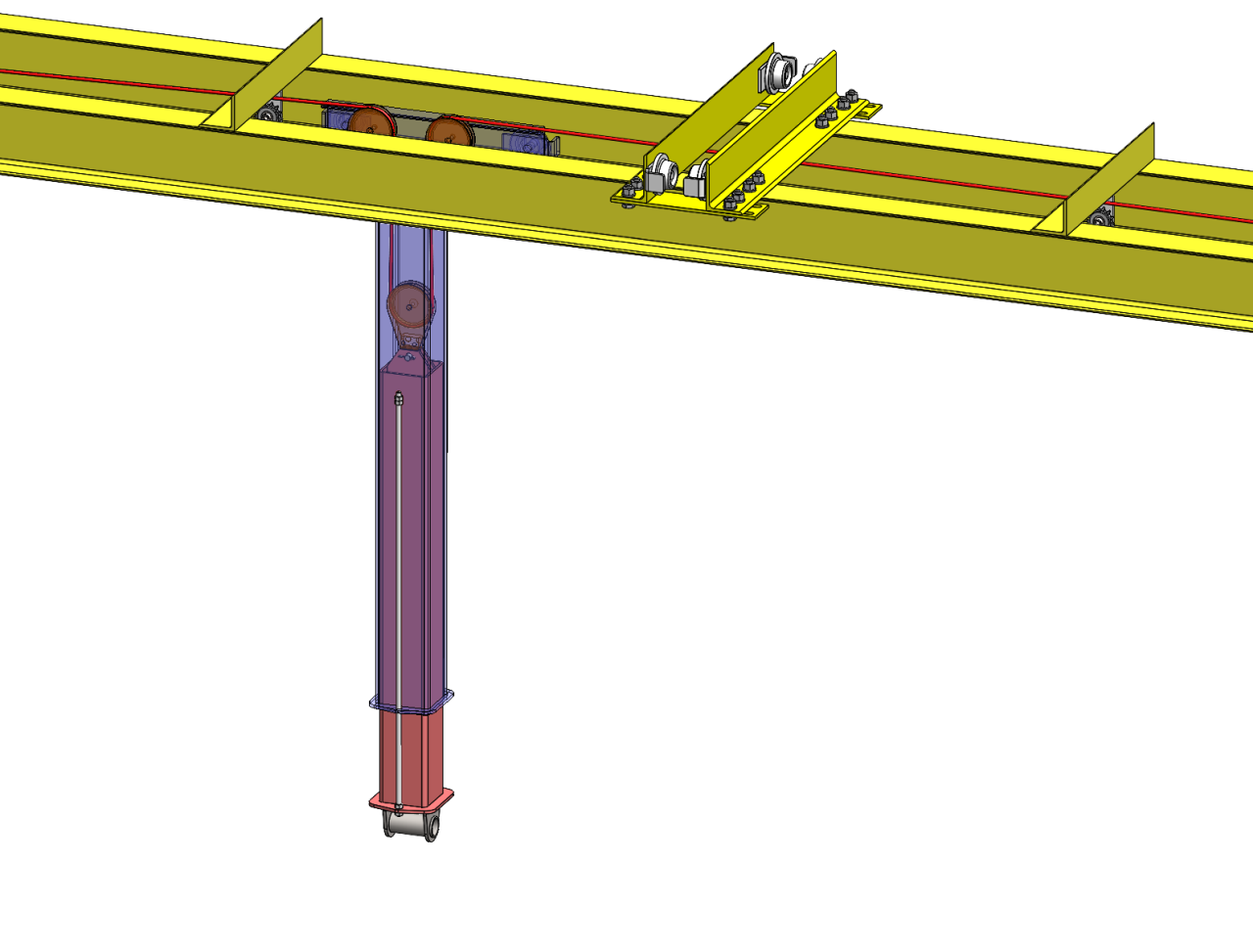

The design is inspired by the tower cranes, where the hoist is placed at the counter-jib end, the wire rope is looped through the trolley and hook block sheaves, then terminated at a fixed point at the far end of the jib.

Chain drives

The travel for both the trolley and bridge is done by employing roller chains, similar to a garage door opener. This eliminates the need for drive wheels, festoon cable, and wheel traction issues due to unequal loading.

DC or Stepper Motors

As the equipment operates between pre-set positions, the logical control can be done either with DC motors and physical limit switches or Stepper motors controlled by a CNC/3D printer-like board, based on a G-Code. The DC motor controller current output be easily tuned to act as a load limiter.