Load Rating of Not Commercially Manufactured Lifting Device

In this post, we will describe the basic steps involved in Certification of a Not Commercially manufactured lifting device. The most common types in this category are monorails and jib cranes.

Visual inspection and Measurements

The first step is a thorough visual inspection to assess the structural integrity and spot any deficiencies such as: deformations, cracks, bad welds, missing or loose fasteners, etc.

Then we take field measurements and specifications: assembly type (bolted or welded), main beam profile, span (distance between the supports), end stops, supporting structure, field sketches, drawings and photos; lifting capacity of existing hoist or required capacity.

Reverse engineering

Based on the information gathered during the site visit, we generate a quick 3D model and drawing for the equipment and determine the critical components that need engineering verification (usually the main beam(s), columns, concrete foundation, etc. If the lifting device is supported by the building structure, an additional Civil Engineering validation is required. Our scope of practice is limited to mechanical and industrial structures, however, we are partnered with a civil engineering company that can validate the pertaining portion of our drawings.

Certification criteria

There are usually 2 criteria that determine the certification of a lifting device:

- tensile stress calculation from bending momentum. Depending on the operation duty and use frequency, we determine the minimum necessary Factor of Safety as follows:

- Infrequent use, intended for a certain piece of equipment, e.i. monorail on top of a pump, FOS >= 2.

- Occasional use, servicing various load types; i.e. a monorail over a rebuild shop workbench, FOS >= 3.

- Frequent use, various load types; i.e. a jib crane with an electrical chain hoist used daily in a production shop; FOS >= 4.

- vertical deflection under 100% load, determined either theoretical or experimental with a load test, at the point of its maximum (center span for double supported beams or jib tip for jib cranes). An article explaining this in more detail can be found here Understanding Overhead Crane Deflection and Criteria – Explore Our Products – Materials Handling Solutions (spanco.com).

Corrective actions

Sometimes quick and inexpensive improvements are required to meet the applicable codes and regulations. in Canada, B167-16 (R2021) | Product | CSA Group governs the Overhead cranes, gantry cranes, monorails, hoists, and jib cranes. Examples: end stops, limits, drop stops, guards, etc.

Load testing

For some equipment, especially if we determine lean safety factors, we will set up a static load test with 100% capacity and measure the maximum deflection.

Deliverables: Sealed drawings and Capacity markings

Once the corrective actions are complete, we deliver the following:

Certification documents

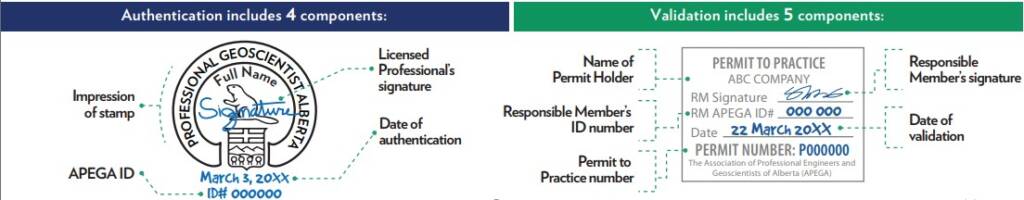

Calculations (or FEA) and a sealed drawing, as required by APEGA: Authenticating Professional Work Products guidelines.

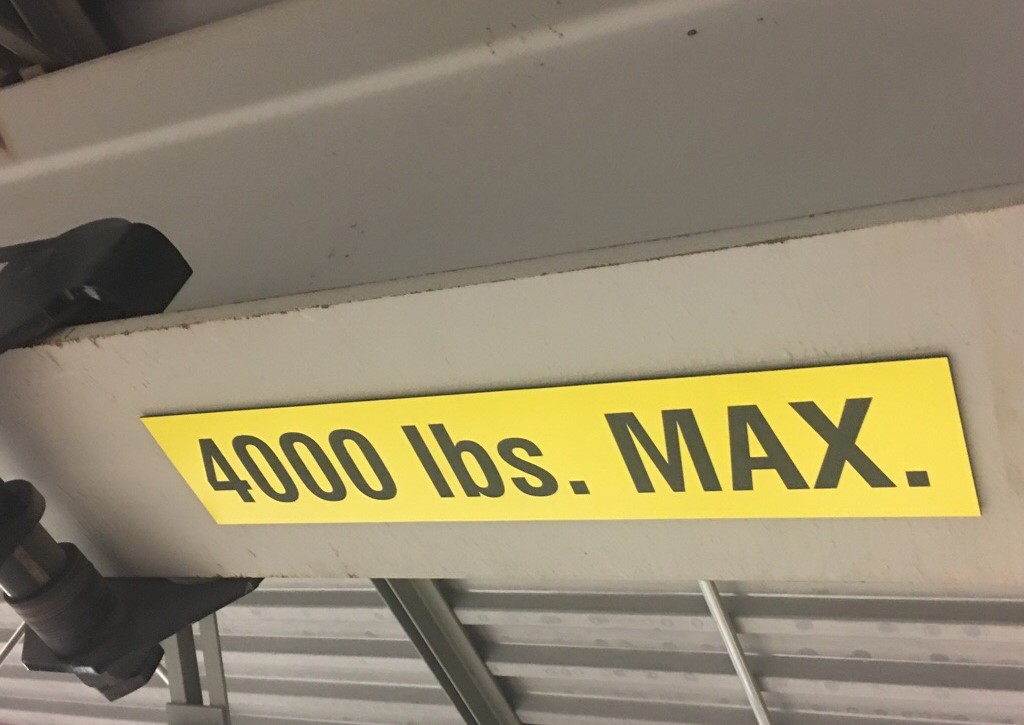

Capacity markings

“plate or weatherproof label permanently secured, … that legibly shows the rated load capacity” as required by Alberta OHS, Art. 62(2).

Pricing

Being a start-up and one-man operation, we have low overhead, therefore we can offer very competitive prices.

The certification of a simple monorail can start at $800 within a one-hour drive and is getting cheaper if the client has more similar equipment.